Services

Screen Printing

Plastisol Ink

The most widely used ink in the apparel printing industry. Plastisol ink is highly verstaile, and it can be mixed to create almost any color.

Puff Print

When puff additive is mixed with plastisol ink, during the curing process, the ink rises. This effect gives off eye catching look and feel to your print.

Screen Print Transfer

This process allows us to print single color artwork onto transfer paper, which then can be heat pressed on to garments. Most commonly used for foam trucker hats.

Special Location Printing

We can print over pockets, zippers, seams, and other non-trandtional placements.

UV Ink

UV Ink is transparent, but when activated in the sunlight, it turns a vibrant cyan, magenta, or yellow.

Glow In The Dark

Glow in the dark ink is transparent, but when in the dark, it glows a vibrant neon green. We also have a red glow option.

Embroidery

Appliqué Twill

Also known as tackle twill – This process uses cut out shapes of twill material and we embroider stitch around the edges. If your graphic has large areas of a single solid color, we can use the twill material for this clean look.

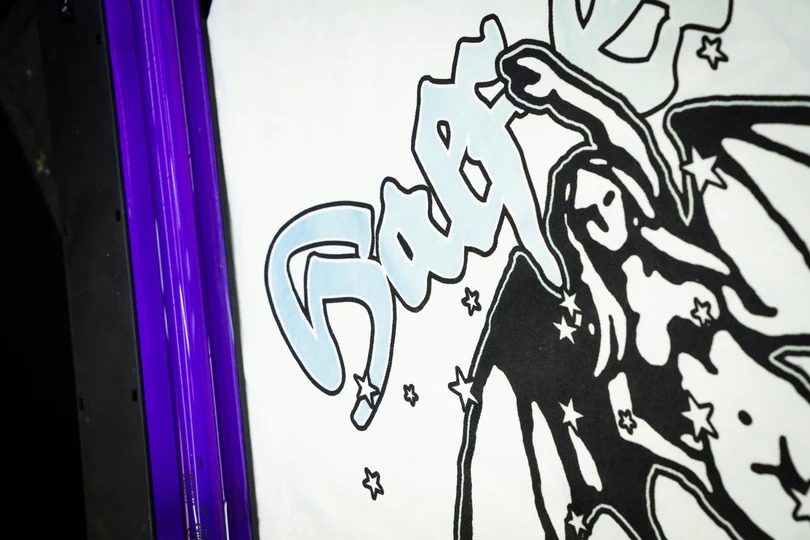

Flat Stitch Embroidery

Using polyester thread, this technique can be applied for most design types. If your design is big or small, simple or detailed, flat stitch embroidery is usually the way to go.

3D Puff Embroidery

We place foam underneath the stitching to create a 3D look. Most commonly used for sports logos on caps. This technique helps the graphic stand out on garments, and looks best with a solid color design.

Flat Stitch + 3D Puff

We can combine these two techniques to add depth to your designs.

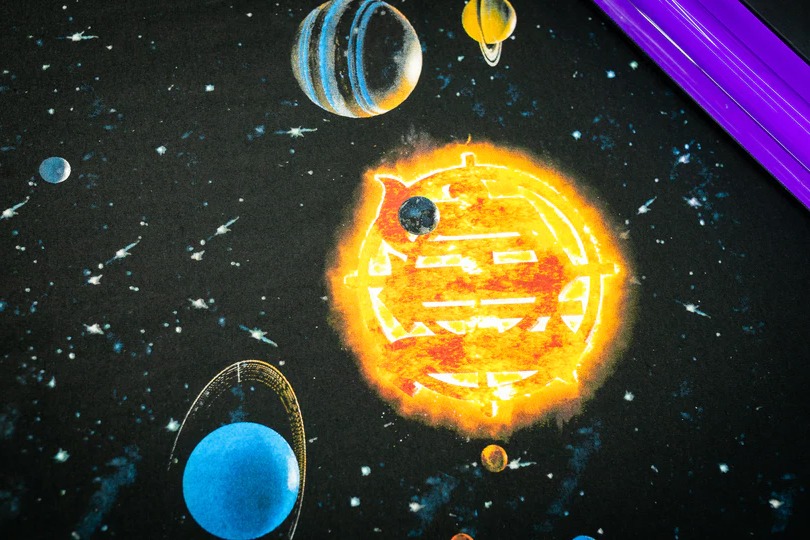

DTG

Direct to garment (DTG) printing uses water based CMYK ink to print your digital artwork directly onto a garment. DTG is the perfect print method for designs with high color, transparency, gradients, and photorealistic images. The main difference between DTG and screen print is that DTG prints any transparency, or color blends smoothly. Screen print would replicate the effects with halftone dots.

Rhinestones

We source our premium rhinestones from a partner manufacturer in Korea. Our rhinestones are highly comparable to Swarovski, but at a fraction of the price. We have over 60 colors for you to choose from, so your designs have plenty of room for customization.

Finishing

Sewn In Woven Labels

We can sew your custom woven labels onto your garments for a premium finish. We can source high density custom woven labels for you if needed. Any design, any size, MOQ starts at 200 pcs for custom labels.

Screen Printed Labels

If you want to remove the original manufacturer tags on your garments and add private labeling – Screen printed size tags are the most popular option.

Hang Tags

We can create fully custom hang tags and apply them onto your garments.

Fold & Bag

Fold and bag services to complete your product. Bagging protects your product and gives your brand a premium and retail ready look.

Bespoke Manufacturing

Screen Printing

Heating Process

Embroidery

Sewn To Perfection

DTG Print

Water Based CMYK Print

Custom Label

Screen Printed

FULFILLMENT

Custom Packaged